by Jodi Smith

published by Spinning Madly, 1995

March 2003 revised

edition

The perfect dyebook for

historical reenactors.

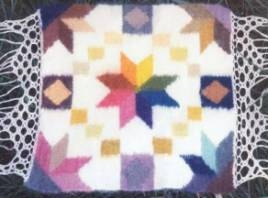

Get authentic, bright colors on wool,

cotton, linen, and silk.

Contains

- Discussion of 48 historical dyestuffs

- Thirty-six natural dye recipes, tested by the author

- Results of the author’s lightfastness tests

- Recipes for scouring fibers

- Updated recipes for mordanting before or after dyeing

- Safety advice

- Discussion of 24 chemicals used in dyeing (What is the difference between “potash” and “pearl ash”?)

- Conversions between traditional “English” and metric units

- Index of dyestuffs by common names and by scientific names

- Annotated bibliography of over 50 sources for further study

- Fun facts (The Romans used walnut husks as a hair dye. “Alizarin”, a pigment found in madder root, is named after the Persian word for madder dye, “al lizari”.)

- 22 black and white illustrations, by the late C. Ellen Young

“… a warm and chatty companion in the dye kitchen …. Medieval Dyes is a handy and thoughtful resource guide and will hold its own in your fiber library.”

Gail Denton, Costume & Dressmaker magazine, January 1997

To Order Your Copy

Paperback book – at Amazon

E-book for Kindle

A Typical Entry:

Weld

Reseda luteola

dyer’s mignonette

Pigment: luteolin

Plant:

An annual or biennial plant, native to Britain, Europe, and the Mediterranean. The dye is produced in the leaves. Wild mignonette, Reseda lutea, gives similar but weaker colors.

History:

The Greek writer Dioscorides, in the 1st century a.d., lists weld as a dyeplant. The Romans used weld to dye wedding garments and the robes of the Vestal Virgins. The Persians used weld dye.

In the Middle Ages, weld was grown as a dyeplant throughout Europe and Britain. Rosetti, writing in Italy, probably in 1548, includes recipes for yellow dye, and for a green dye on linen using weld and verdigris.

Weld continued in use until the 19th century when “old” fustic and quercitron became more economical yellow dyes.

Dye:

Weld has the reputation of not being a very concentrated dye (compared to fustic or quercitron), but it is more concentrated than many dye flowers.

Weld works best with a slightly alkaline dyebath.

Keep the bath well stirred because the pigment tends to settle to bottom of pot.

Do not boil the dyebath, as boiling may make the yellows turn brownish.

Weld gives lemon yellow on wool and silk with alum mordant, greenish yellow with copper, and olive with iron. The colors are lightfast. There are mixed reports on how successfully weld dyes cotton.

Recipe:

Use dried leaves, equal to 1/2 the weight of fabric.

Crumble the leaves and soak in warm water 6 hours.

Add a pinch of washing soda and the fibers. Simmer fibers 1 hour.

wool & silk cotton & linen

alum: yellow yellowish brown

alum & copper: yellow yellowish brown

copper: brownish green yellow

iron: dark greenish brown brown